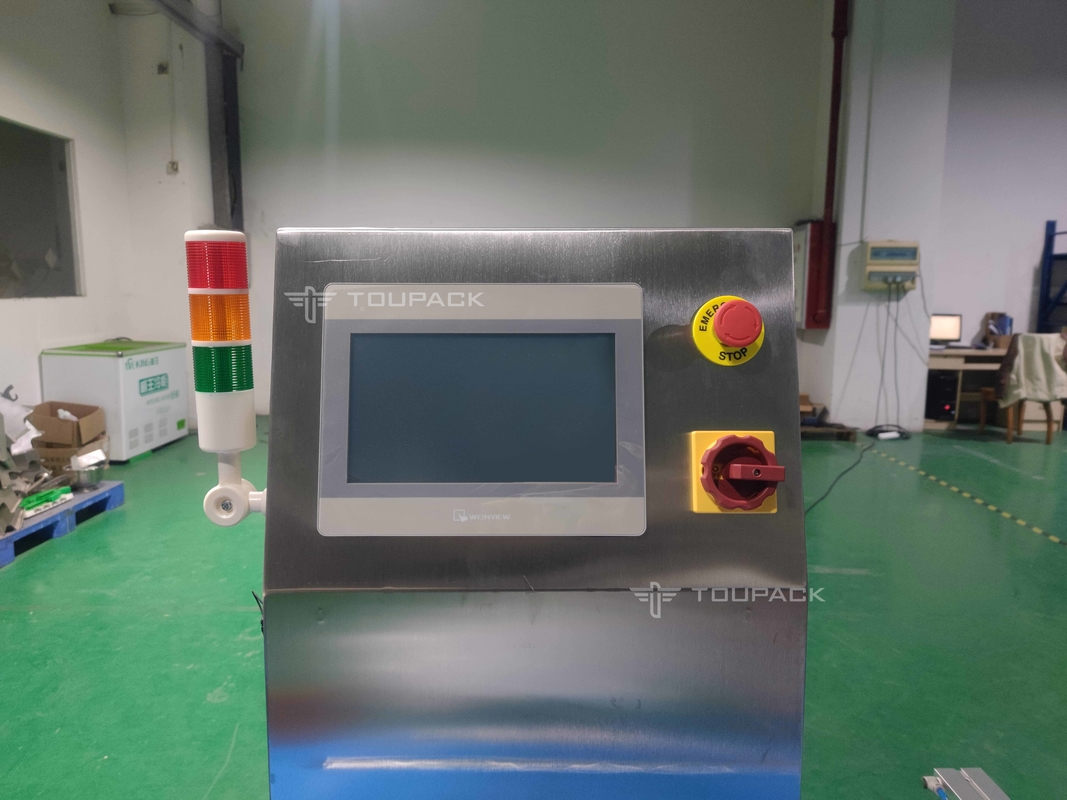

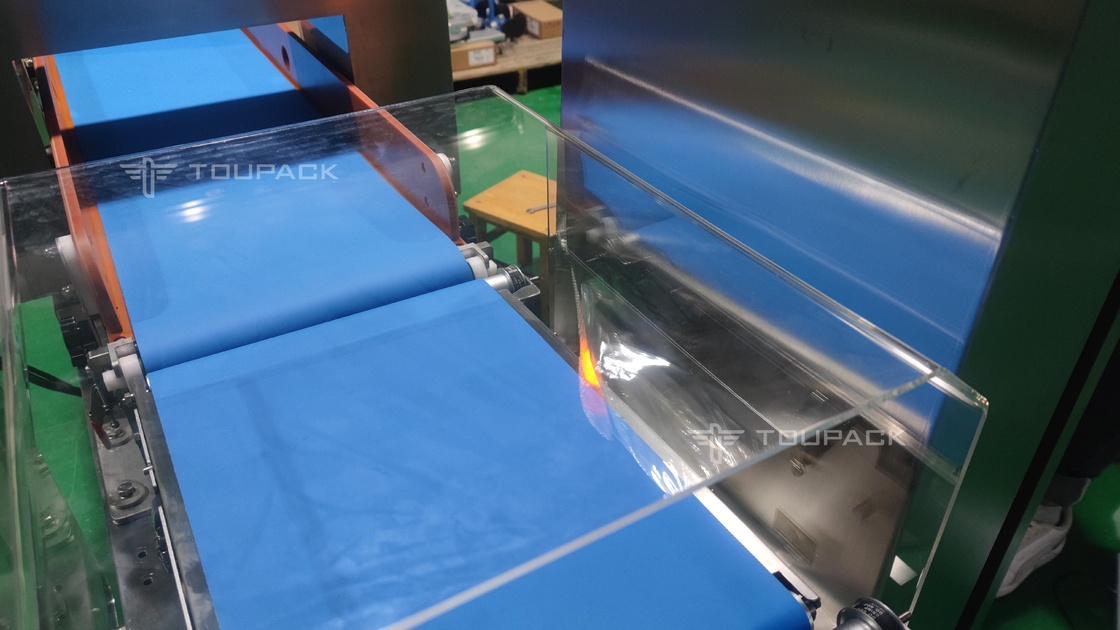

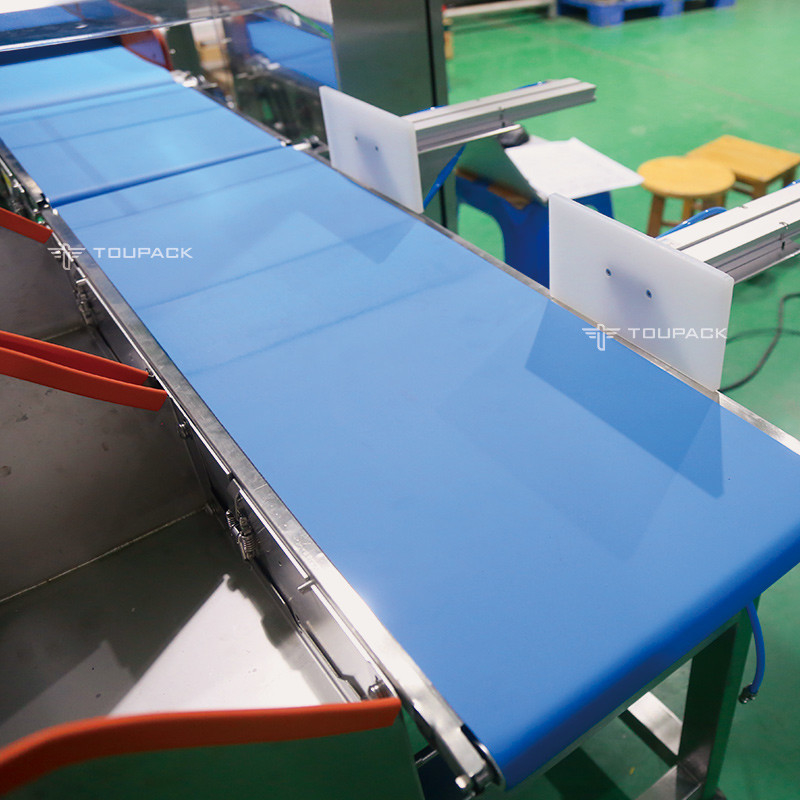

GUANGDONG TOUPACK INTELLIGENT EQUIPMENT CO., LTD

Since 2002,We entered in High-tech industry and TOUPACK has established in 2009,working in weighing,packaging,conveying,multi-weight sorting mechine.

We'll get back to you as soon as possible.