The Multi-material Mixing weighing and packaging system is an advanced automated equipment specifically designed to handle and package many different types of materials, mix them in predetermined proportions, and pack them after accurate weighing. Such systems are commonly used in the food, chemical, pharmaceutical and other industries, where precise mixing and packaging of multiple raw materials is required.

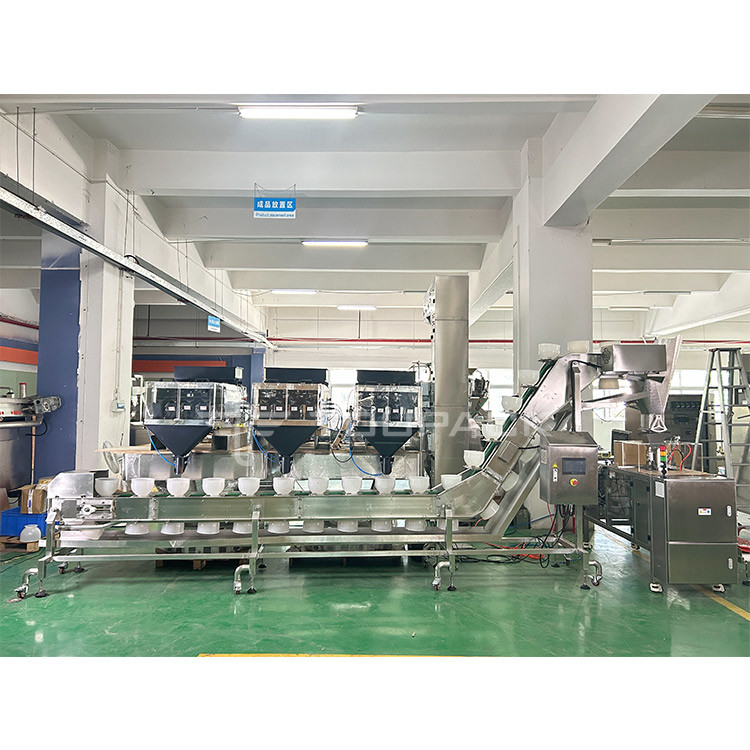

※Solution: 4-head linear weigher + Bowl-Type Elevator + Self-supporting zipper bag single station bag packing machine

※Weighing materials: oatmeal, corn flakes, popcorn, cereal, chopped dates, cranberries, raisins, sesame seeds, almonds

※Target weight: 250g/bag

Specifications:

|

Model

|

TY-ZX041M30-02-11

|

|

Max. Weighing (one hopper)

|

20g-2000g

|

|

Accuracy

|

x (0.5)

|

|

Max. Scale Interval

|

0.1g

|

|

Max. Speed

|

40 BPM

|

|

Hopper Volume

|

3.0L

|

|

Control System

|

MCU

|

|

HMI

|

7’’ / 10”color touch screen

|

|

Power Supply

|

AC220V / 110V ±10% 50HZ/60HZ, 1.0KW

|

|

Packing Dimension

|

1510mm(L)*1020mm(W)*950mm(H)

|

|

Net Weight

|

163kg

|

|

Package weight

|

230kg

|

Main Function & Features:

1. 7” color touch screen, multi-language option and software upgraded through USB.

2. Machine body with SUS304/316 for option and IP65 dust and water proof design.

3. Factory parameter recovery function, able to preset 99 product parameters to meet a wide range of customers’ needs.

4. Automatic amplitude adjustment for more convenient operation.

The Multi-Material Mixed Weighing and Packaging System was designed to increase productivity and ensure packaging accuracy. The system utilizes state-of-the-art technology including three four-head linear weigher, Bowl-Type Elevator, and a self-supporting zipper bag single-station bagger to meet the complex weighing and packaging needs of multiple materials.

In this system, a total of 11 different materials need to be mixed and weighed. In order to ensure that each bag of product is an accurate combination, three linear weigher are responsible for weighing each of the four materials. This division of labor improves productivity and ensures weighing accuracy.

In order to cope with the stickiness of certain materials, the surface of the linear weigher is coated with a black Teflon coating. This design is not only aesthetically pleasing and durable, but also prevents the sticking of materials such as dried cranberries and raisins during the weighing process, ensuring that every weighing is accurate.

The weight of each bag of fruit cereal is 250 grams, while the speed of the whole packaging system can reach 60 bags per hour. This high production speed not only ensures the stable operation of the production line, but also meets the rapid changes in market demand. The stability and precision of the entire system makes it an efficient hybrid weighing and packaging solution that provides reliable production support for the manufacturer.

Customization Solution:

According to your production line requirements, our experts will provide you with an integrated weighing and packaging solution to help you improve production efficiency.